CIMSA Ingenieria de Sistemas participates in national and multinational projects involving aerodynamic activities. Aeronautical engineers use powerful software tools for simulating and evaluating aerodynamic behaviour of both rigid and flexible systems. Due to its main production activity consisting in manufacturing textile based wings and recovery systems, CIMSA Ingenieria de Sistemas must

analyze in detail aerodynamic, structural and aero elastic characteristics of payload bodies and decelerators. Wind tunnel tests are used to measure relevant aerodynamic parameters at different wind and environmental conditions.

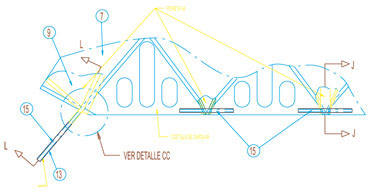

In the field of software development, CIMSA Ingenieria de Sistemas has developed a proprietary

comprehensive graphic design and simulation tool to map air pressure distributions and wind velocities for textile decelerators for a wide spectrum of uses including large paraglider systems and solid rocket boosters recovery parachutes.

CIMSA Ingenieria de Sistemas has set up a research laboratory with electronic equipment to perform static and dynamic testing of textile decelerators. The laboratory designs, develops and installs all required special equipment to measure and gather specific data from the parachutes, such as velocities, accelerations, altitudes, etc., or any other type of flight characteristic.